Process Options

The Process Options (on the left side of the screen) are a set of parameters that control the behavior of the CAM engine.

Process options can be saved in a profile, so they don't need to be reset each time a material is changed.

Operation defaults are stored in a profile as well but are modified within that operation.

Each operation has parameters that can be hovered over to reveal their description.

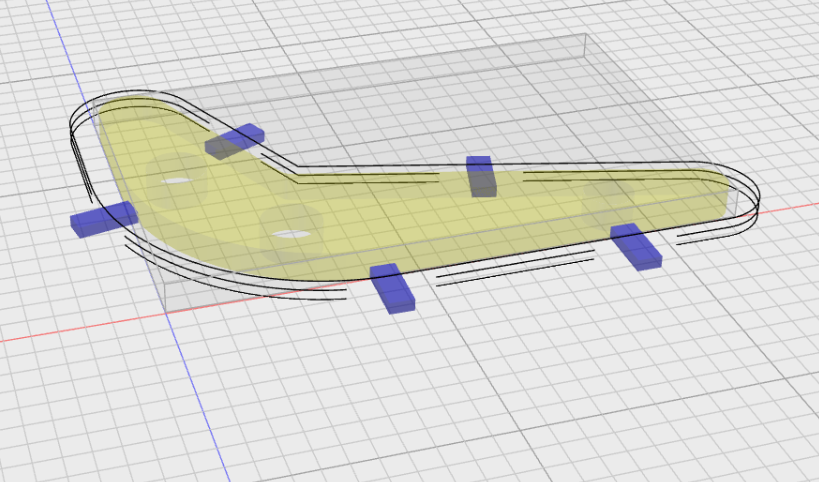

Tabs

Tabs can be added with the plus button, finalized with the checkmark, and removed with the trash button.

Their size is configurable.

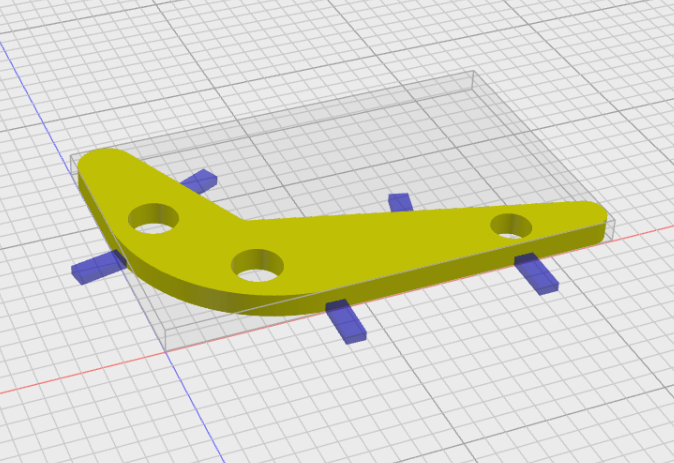

Stock

The stock defines the material that surrounds the part. As of V4.1, only rectangular stock is supported.

Setting width, depth, and height to zero will make the stock the same size as the part's bounding box.

The stock size defaults to absolute dimensions but can be made to offset from the part's bounding box by setting the stock offset option to true.

If the stock is smaller than the part, the part will not slice.

The "Clip To" option will delete any toolpaths that go outside the stock.

Using indexed stock is supported (barely). If you are using a rotary indexer, you can check the Indexed option and use Indexed Operations to create operations on different faces of the part.

Limits

The Limits tab has options for setting the maximum feed rates, the Z-zero, and defaults for top and bottom offsets for operations.

Some operations have overrides for these values.

Output

The Output tab configures how lines generated by the CAM ops are processed before being exported.

These mainly affect what to do before and after each operation, and which direction to traverse the toolpath (climb or conventional).

The First Z Max and Force Z Max are safety features that move to a safe Z

before the job and before pockets, respectively. They are not checked by default for legacy compatibility.

Origin

The Origin tab controls the origin of the part and allows configuration in the form of XYZ offsets.

Expert

The Expert tab controls advanced options for CAM mode, which can speed up slicing but may generate tool crashes.

Use with caution.