Operations

Ops—not to be confused with opps—are the operations applied to a model to remove material. The Operations tab also contains meta-operations that represent parts of the manufacturing process but do not necessarily generate toolpaths.

Each operation has parameters which can be hovered over to reveal their description.

When an operation's settings are changed, they update the defaults for that operation when it is created in the future.

These operations include:

- Toolpath Operations

- Gcode

- Laser Operations

- Indexed Operations

Global Operations

Operations that apply to all objects in the workspace.

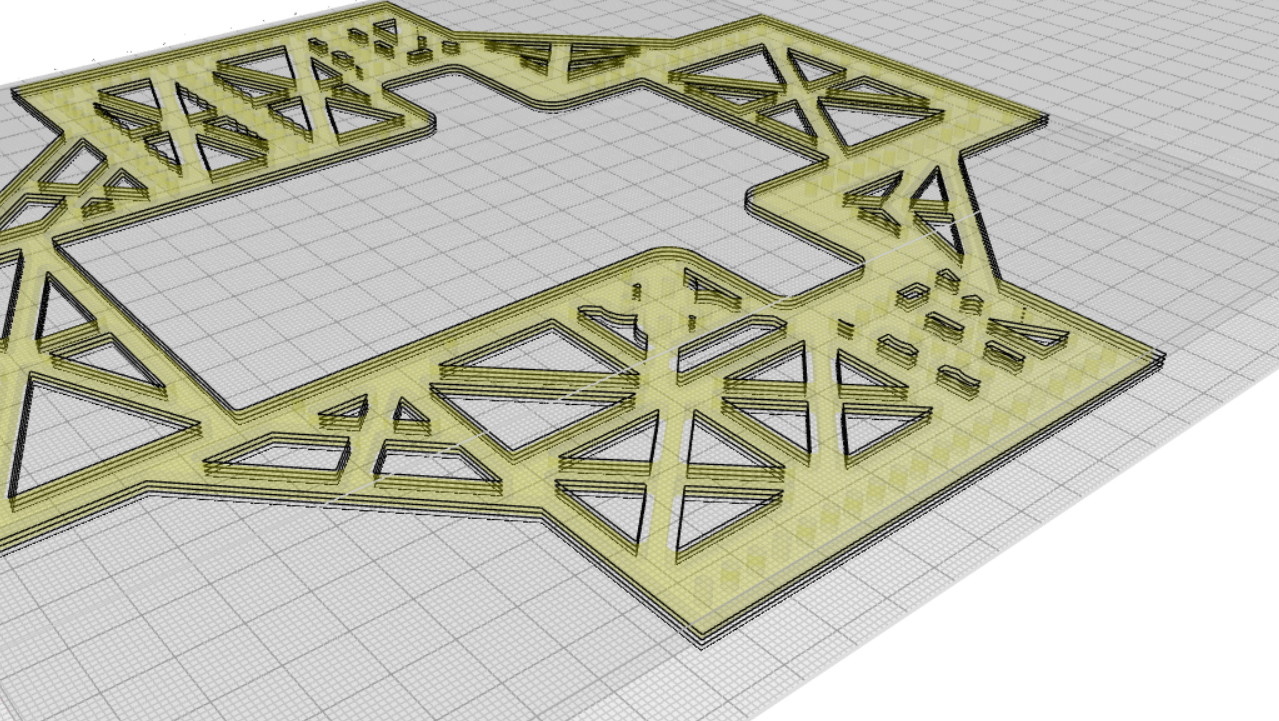

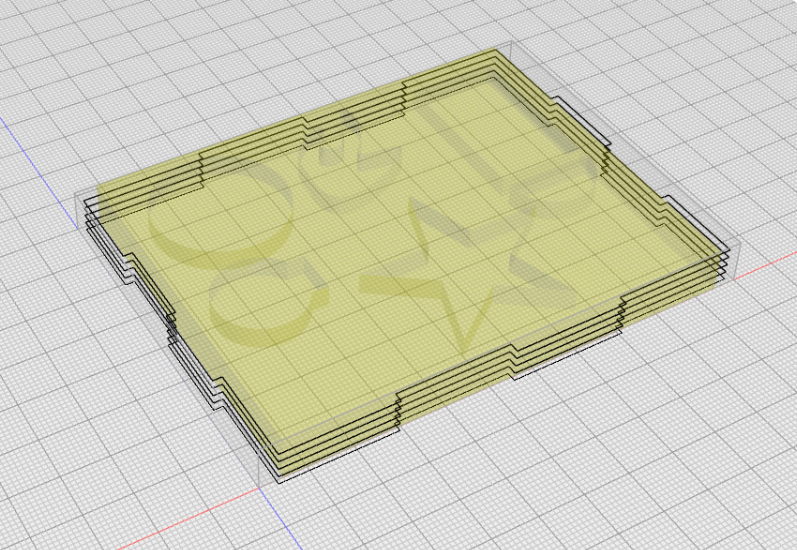

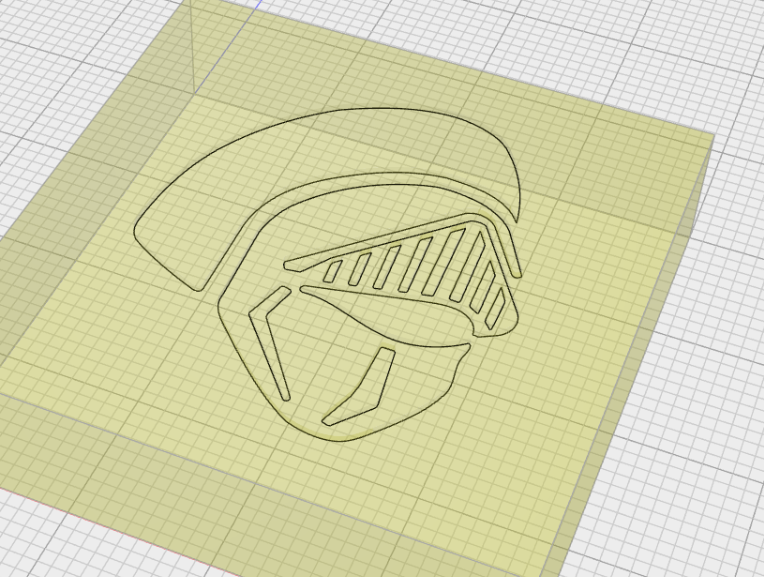

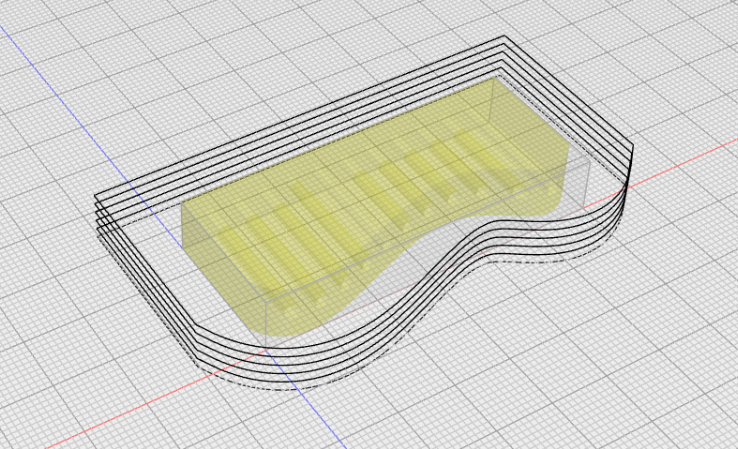

Outline

The Outline op generates a toolpath surrounding the edges of a part. It is highly configurable and can select both internal or external edges specifically. The Outline operation is great for:

- Cutting out many objects at once

- Generating a rough/finishing pass on an object

- Easily avoiding specific features like pockets or holes

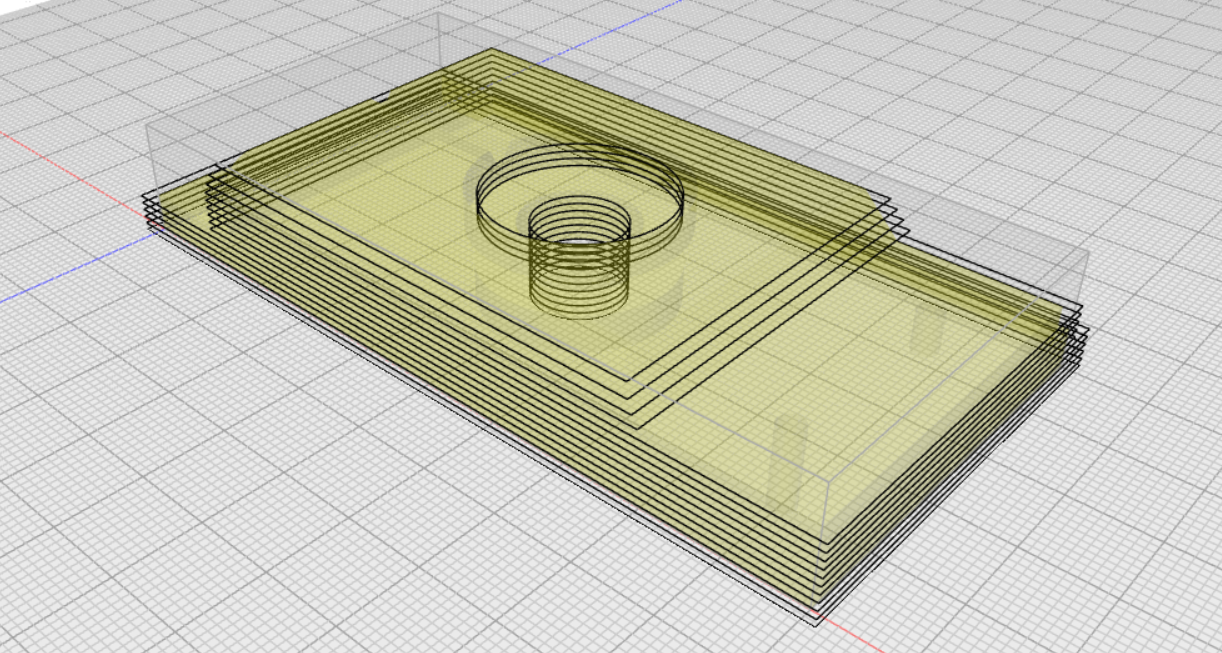

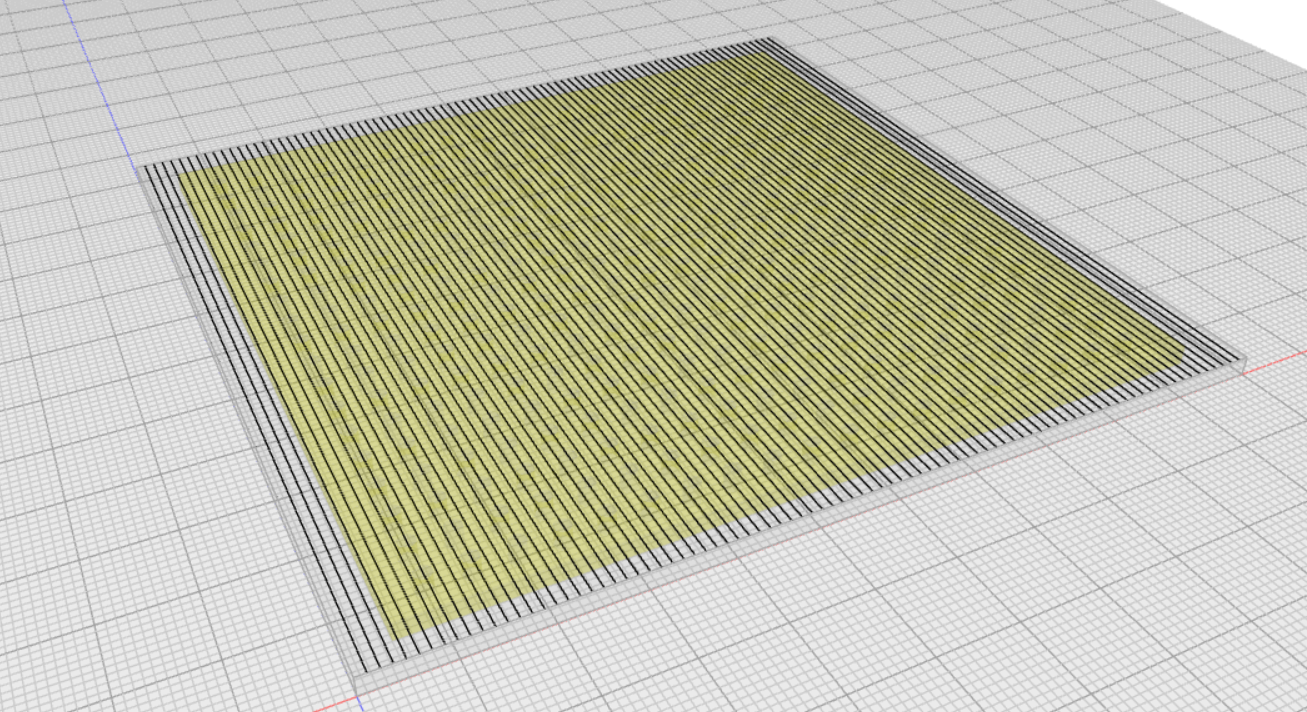

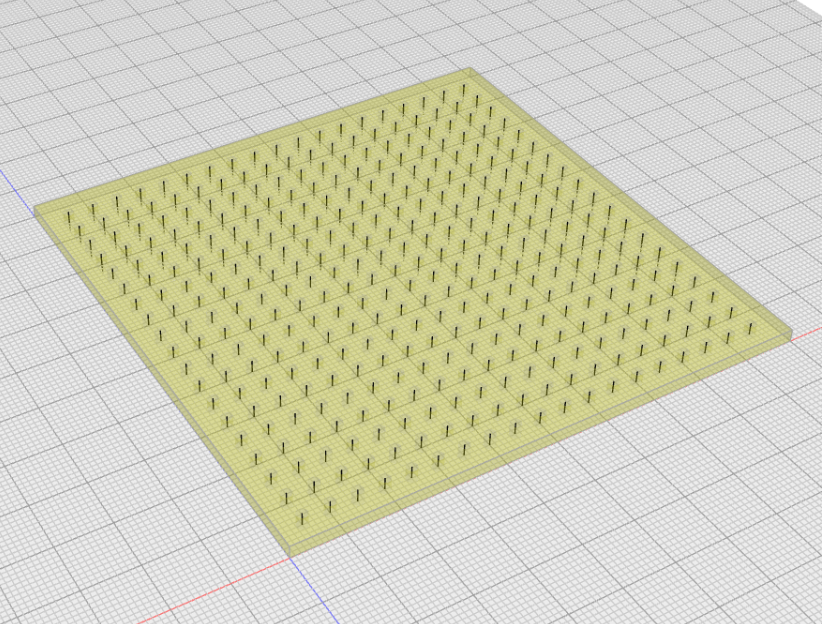

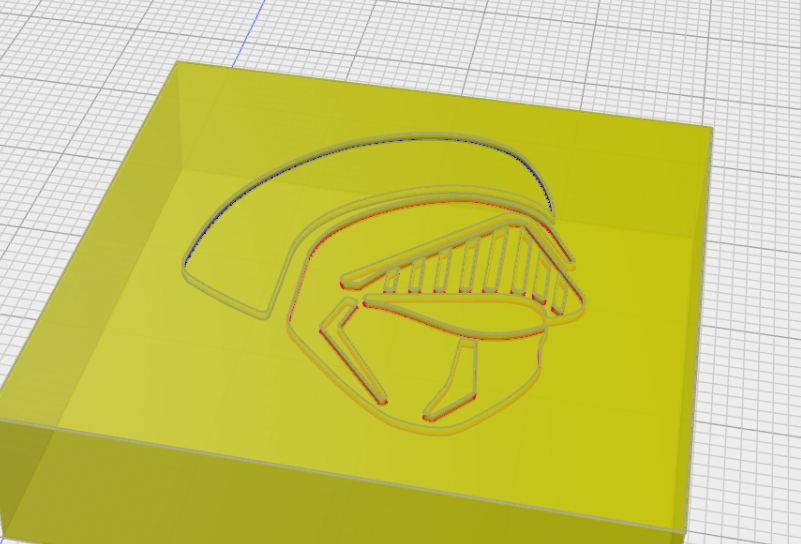

Level

The Level op creates a flat-surface clearing toolpath across a selected area. It is designed to remove material to a consistent depth, making it useful for preparing stock, flattening uneven surfaces, or cleaning up residual material. The Level operation is great for:

- Surfacing raw stock before detail cuts

- Creating uniform faces on complex objects

- Clearing large areas with consistent depth quickly

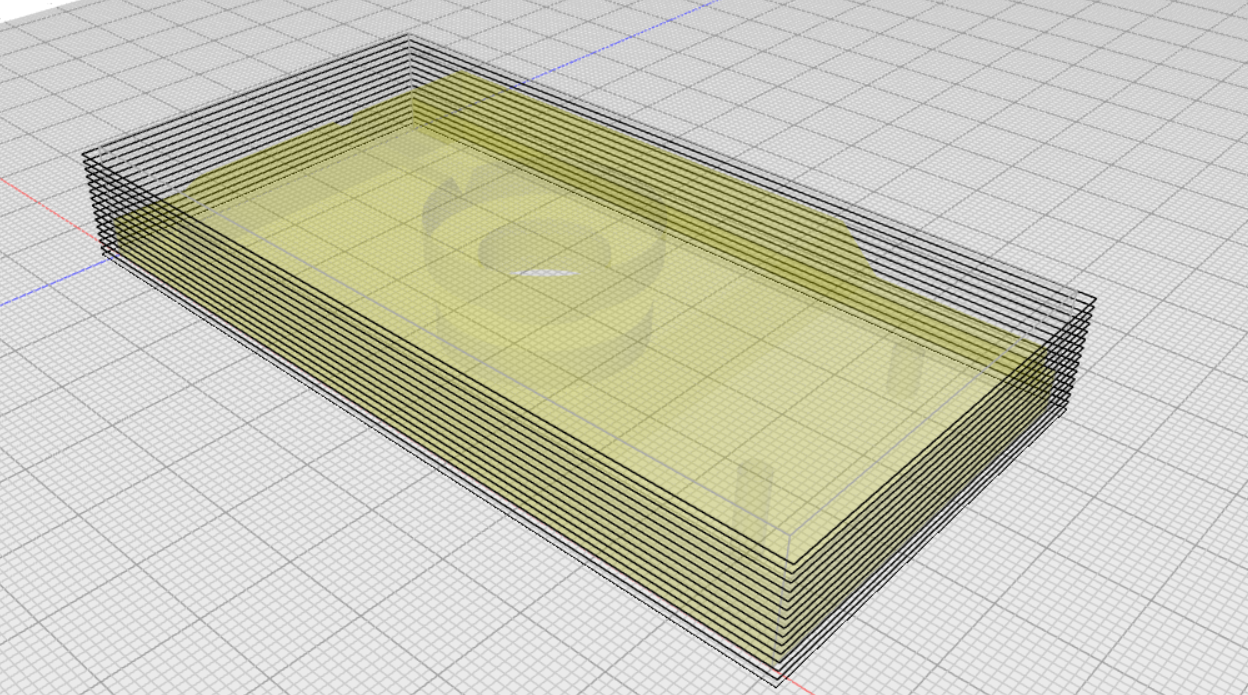

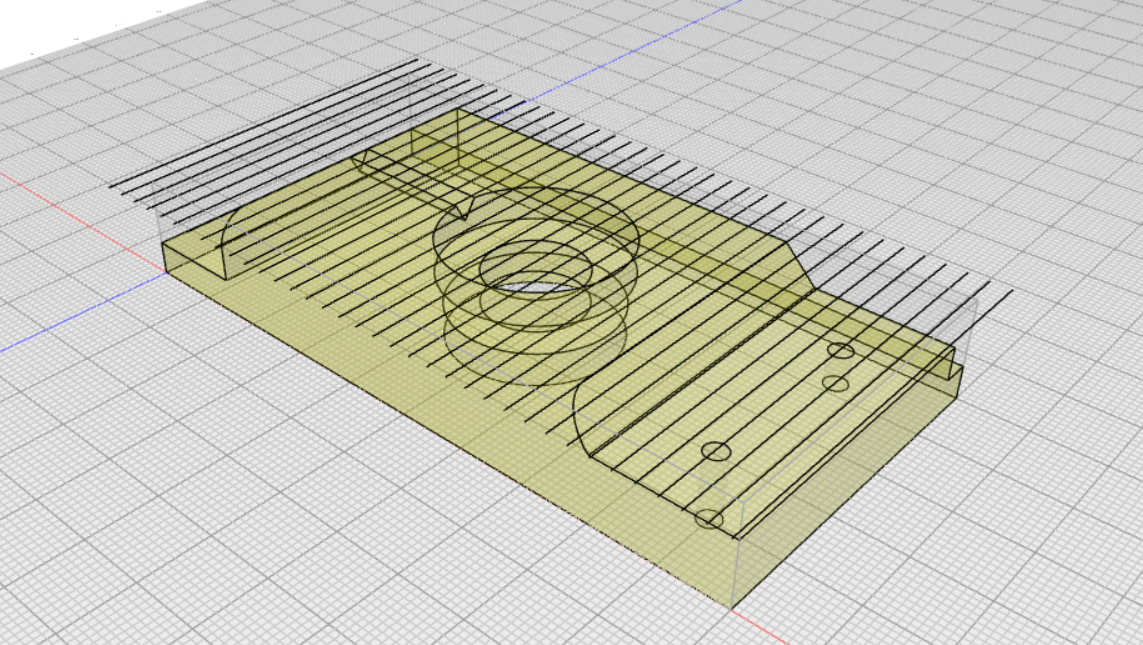

Rough

The Rough op removes large volumes of material quickly using a stepped-down toolpath. It is typically the first pass in a multi-step workflow, clearing space for finishing tools without concern for fine detail. The Rough operation is great for:

- Rapid bulk material removal

- Preparing many parts for finishing simultaneously

- Clearing voids or flat faces for many objects at once

- Preparing a part for finish machining

- Preserving tool life by reducing cutting load in later passes

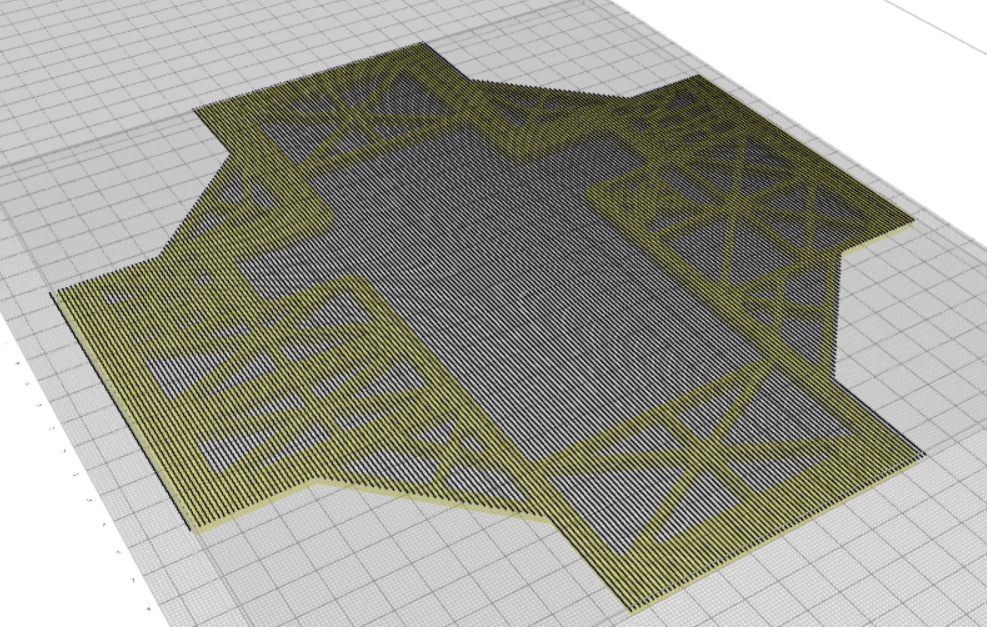

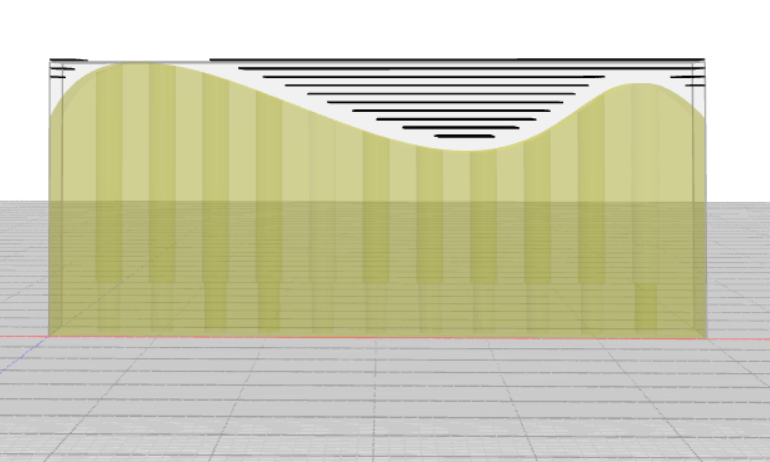

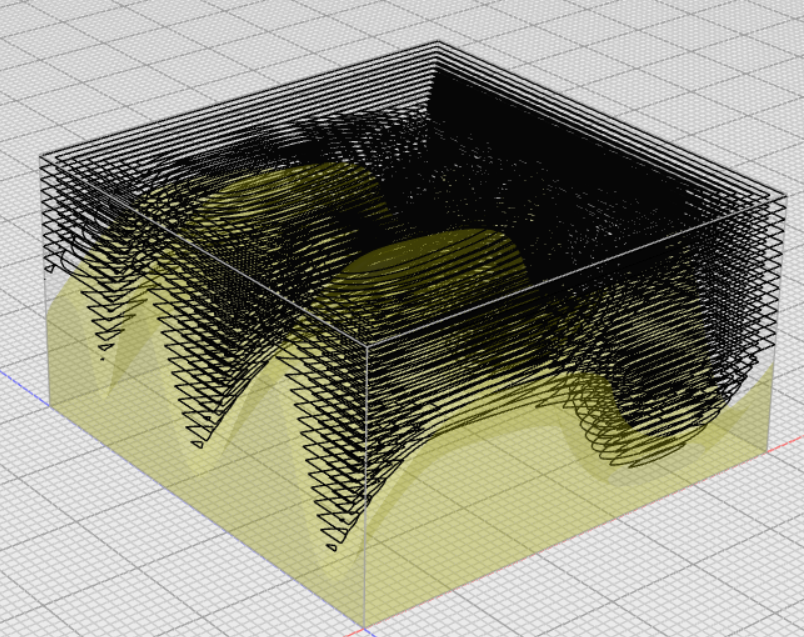

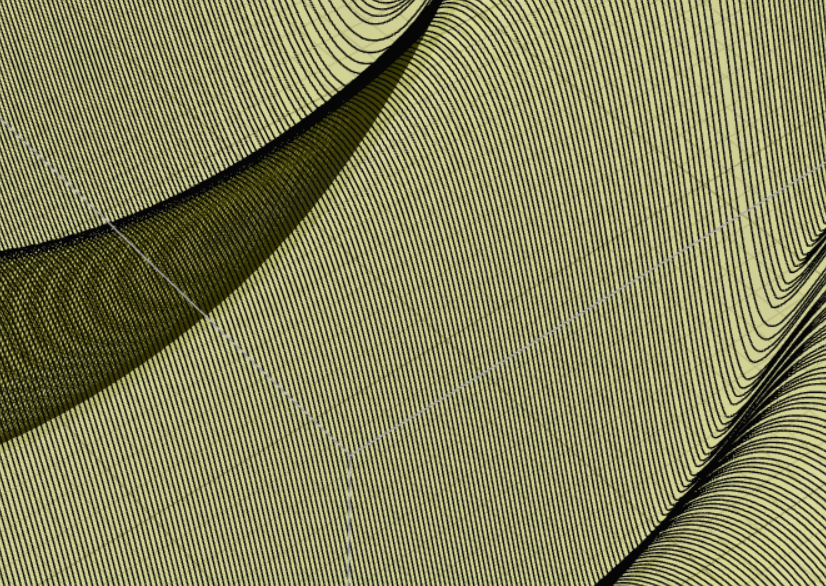

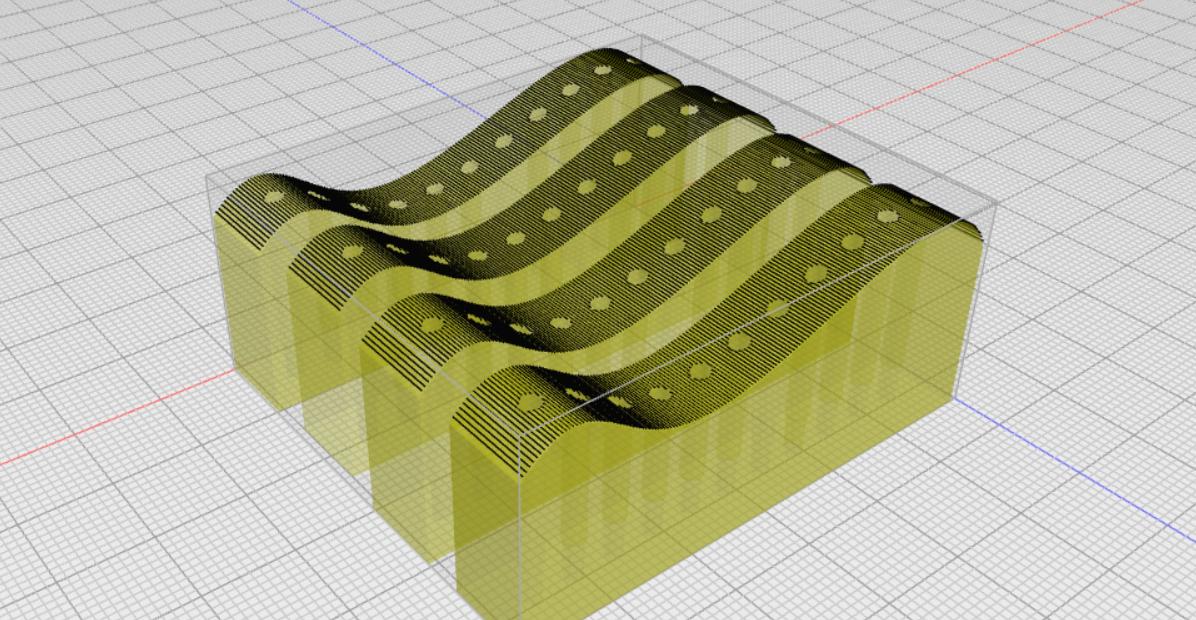

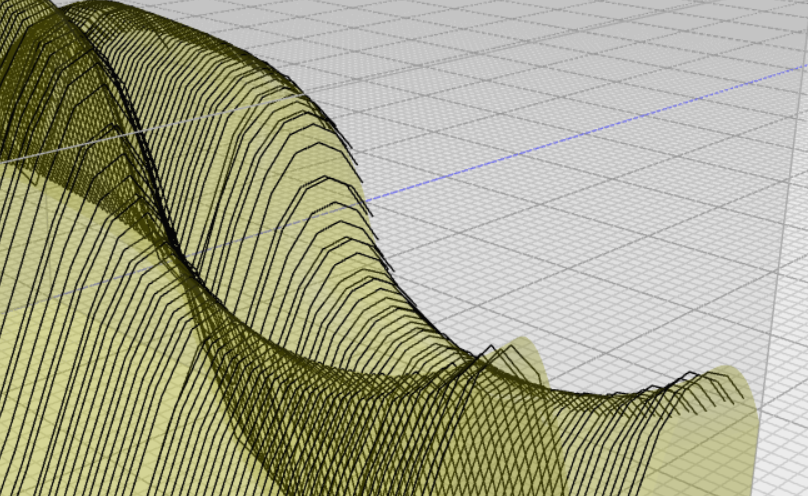

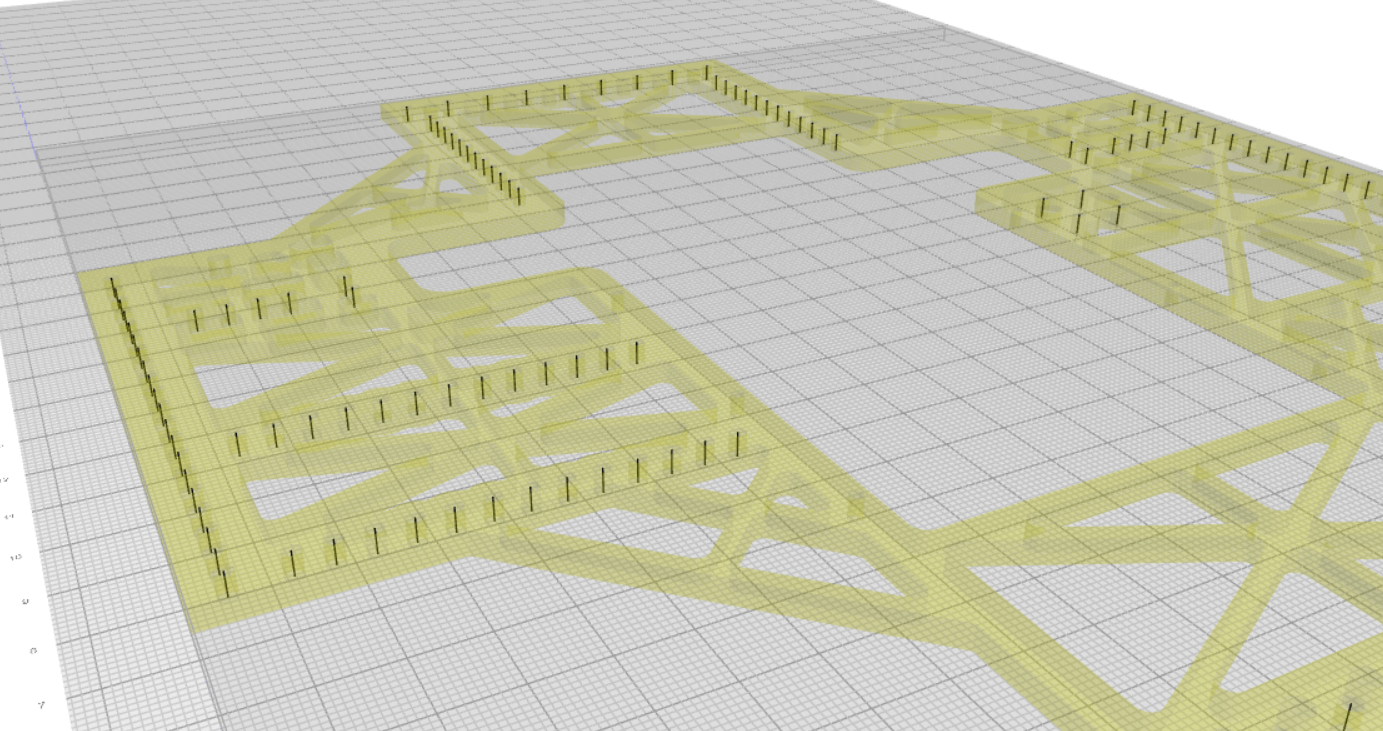

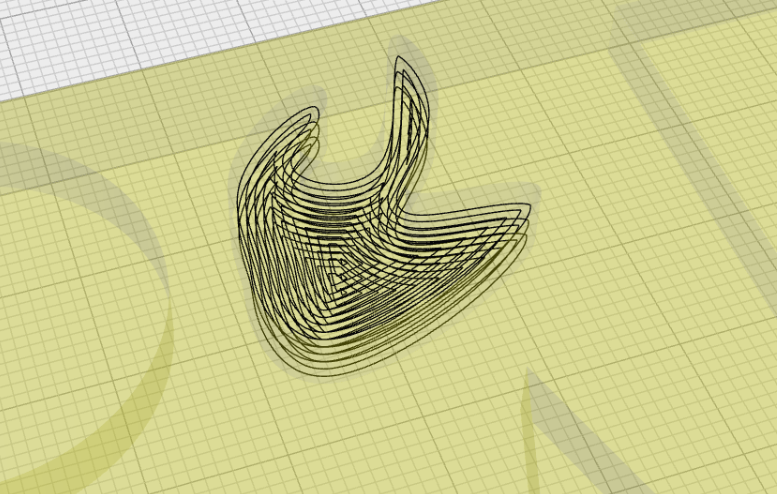

Contour

The Contour op generates detailed toolpaths for complex organic surface geometries.

It can trace along the X or Y axis and has configurable precision. It is useful for:

- Carving 3D shapes with organic or curved profiles

- Finishing complex wall geometries

- Cleaning up a part after roughing

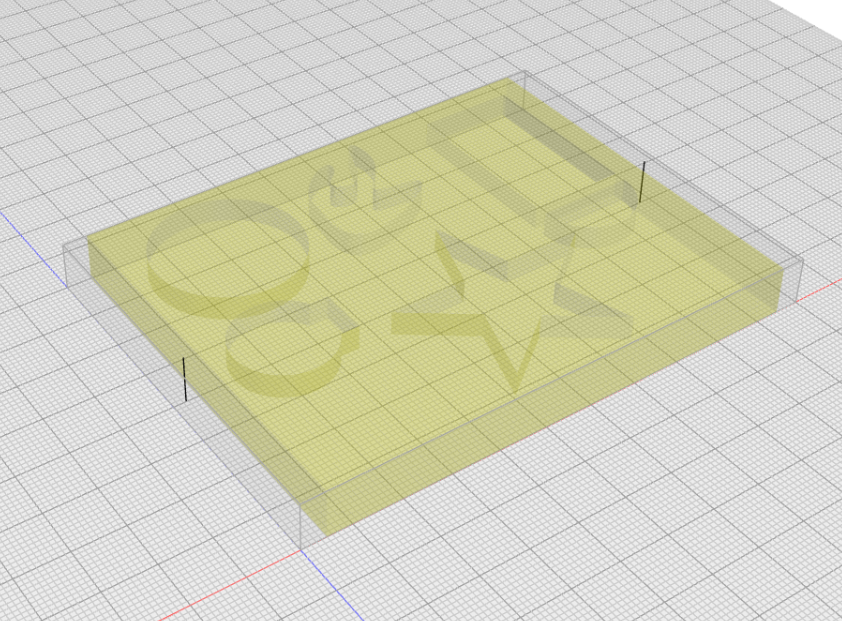

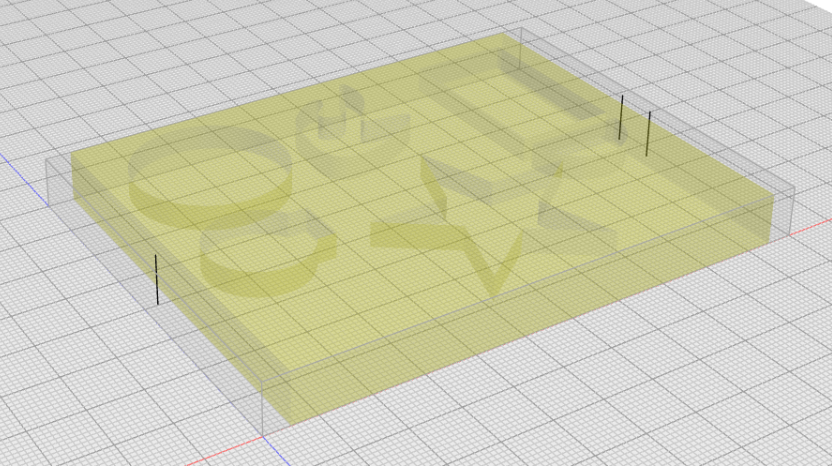

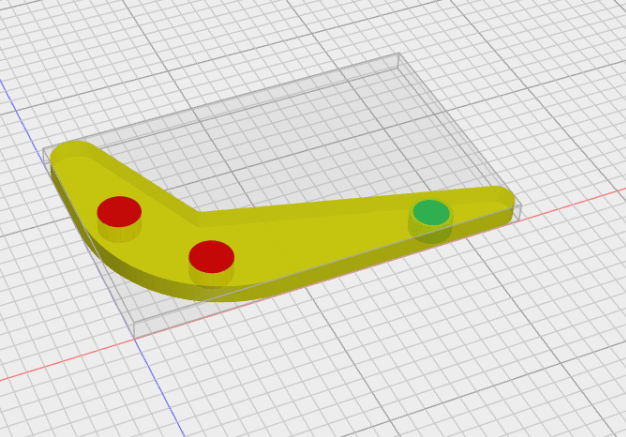

Register

The Register operation drills holes in the sides of a part,

helping keep the part in the same place when it is flipped onto its opposite face.

The operation has options to drill on different sides and can even generate a puzzle-piece-like pattern for registration.

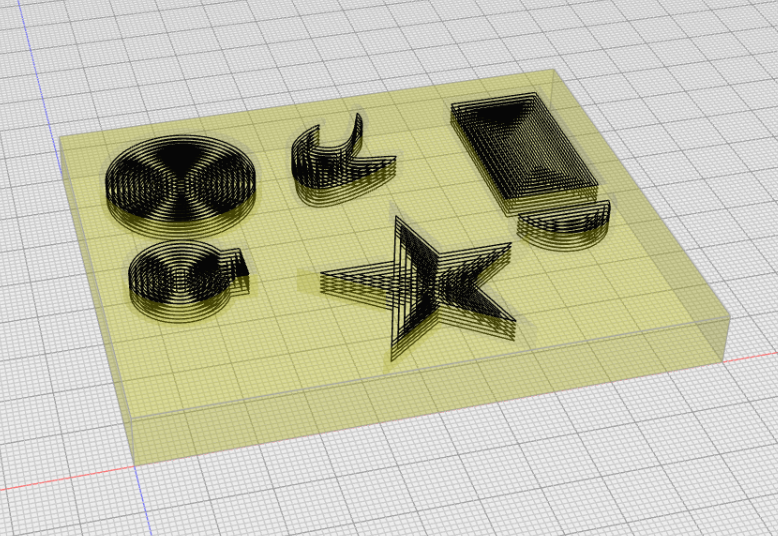

Specific Operations

Specific operations require selection of individual part features to apply operations to.

These may overlap with Global operations but are generally more configurable.

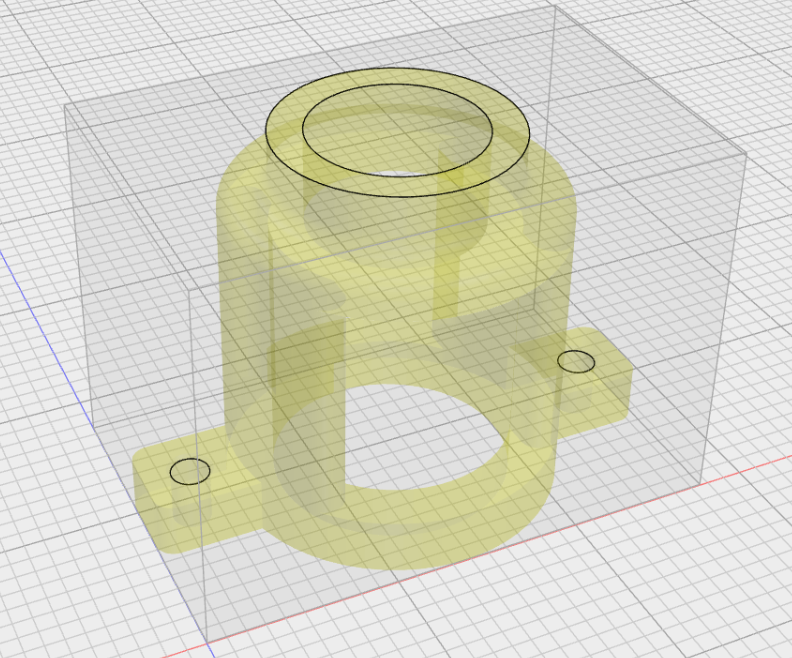

Drill

The Drill op creates pecking toolpaths for a drill tool to follow.

It can also drill holes of other diameters and even mark holes instead of drilling.

It is useful for:

- Generating a toolpath for a drill tool

- Selecting specific holes to remove material from

- Marking holes to be drilled manually

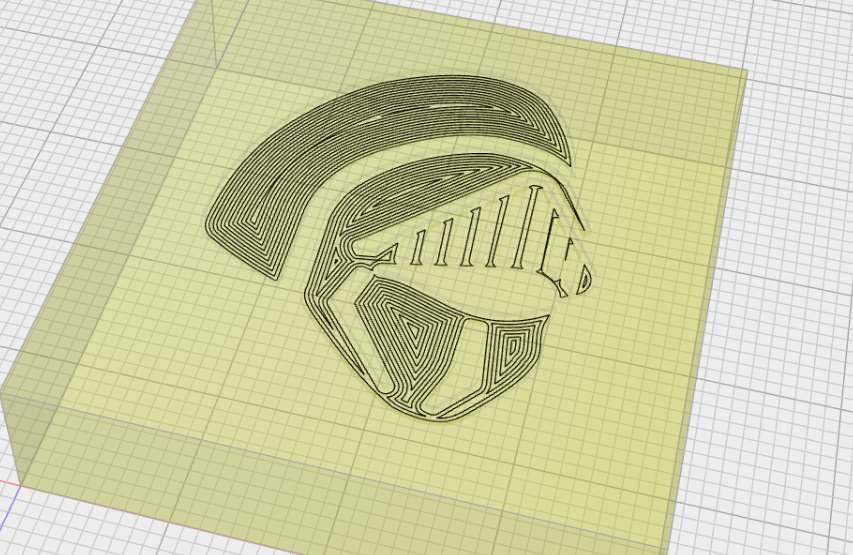

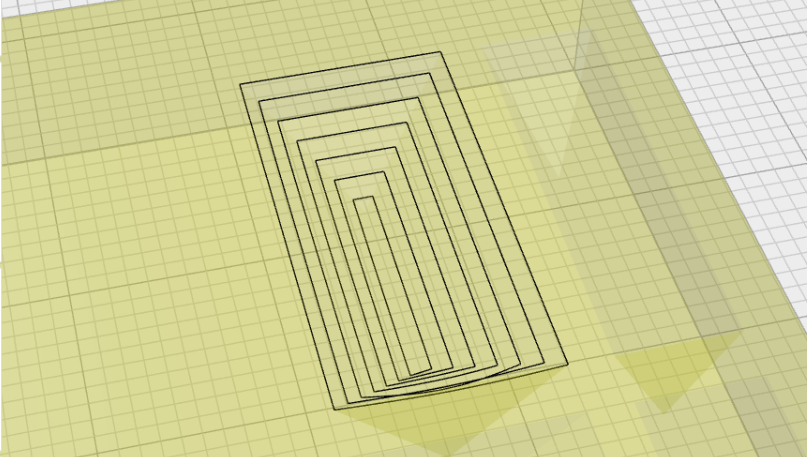

Trace

The Trace operation is likely the most configurable, allowing for generation of toolpaths following loops or lines.

It can trace on, inside, or outside a line and can take multiple passes to step down to the desired position.

When the type parameter is set to "clear," it can even act like a Pocket,

clearing the area above the shape created by the selected lines or loop.

While the Trace op can do a lot, some specific use cases include:

- Engraving lettering or other text

- Drilling out a hole helically

- Outlining a part with a nonstandard offset

- Outlining only one part on the workspace

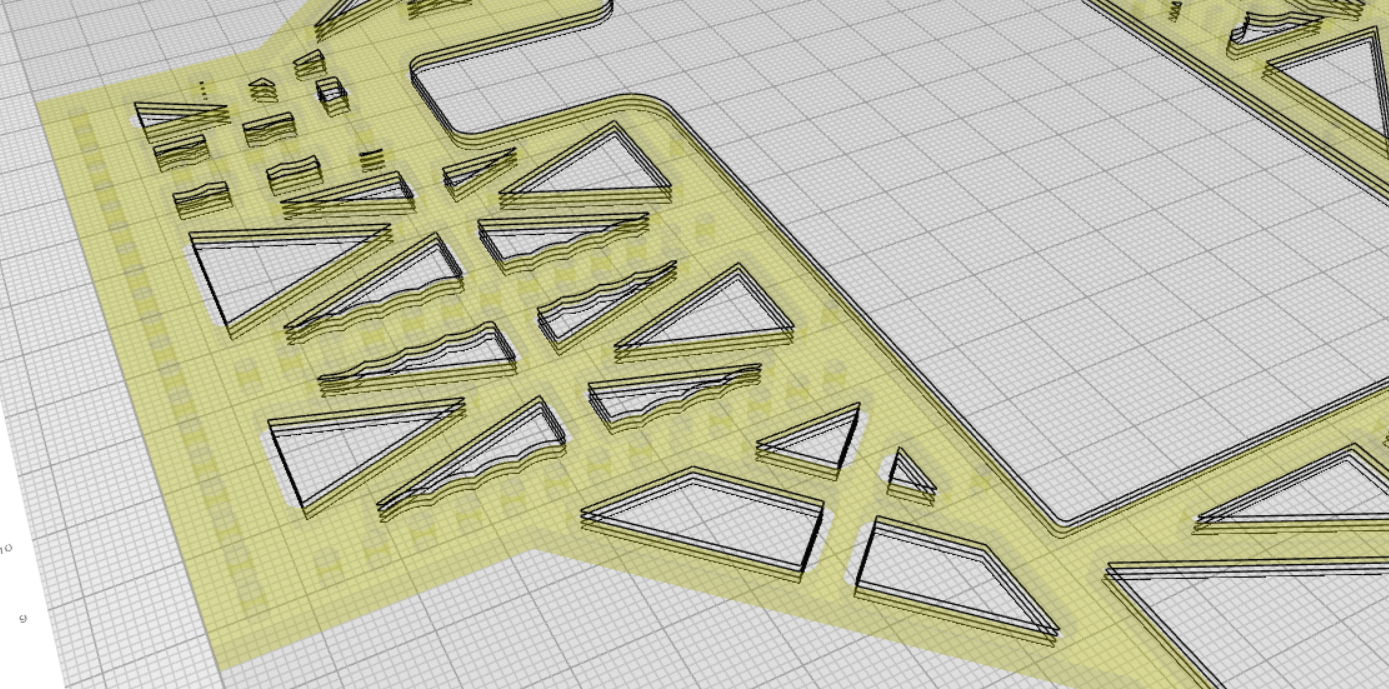

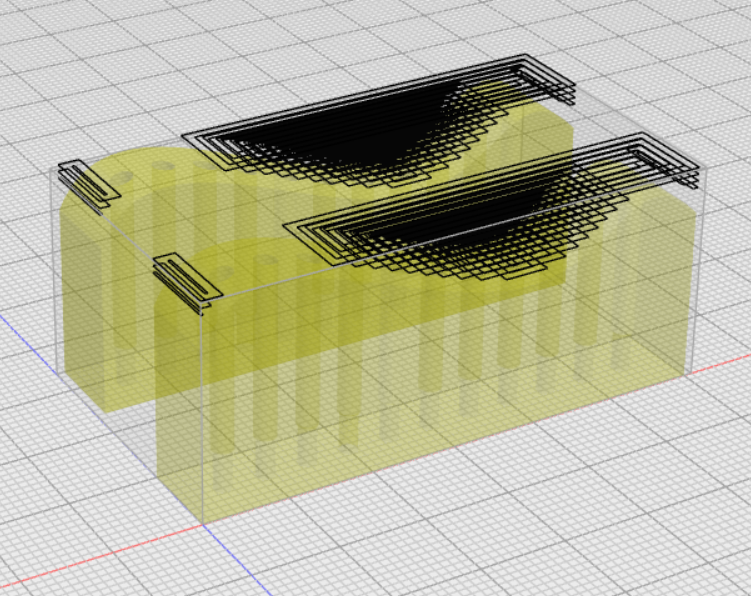

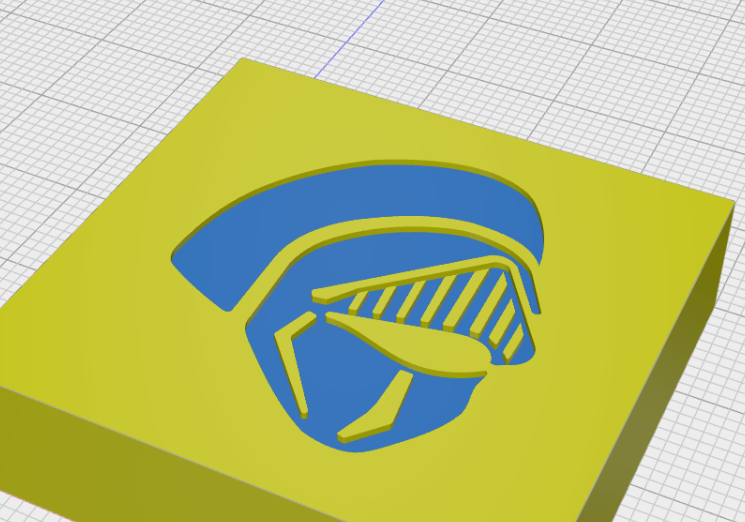

Pocket

The Pocket operation takes a selection of polygon faces and generates a pocket toolpath that cuts down to them.

The operation has options to expand and smooth the pocket selection, and the contour option even allows

for an approximation of a v-bit carve. Some use cases specific to the Pocket op include:

- Creating one pocket in a part with multiple

- Attempting a v-carve

- Clearing a specific area of a part

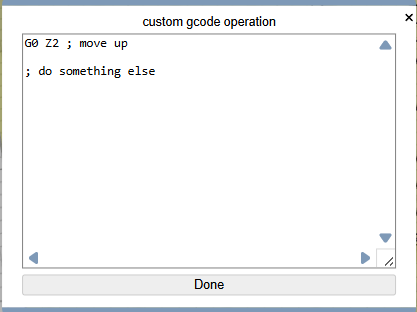

Gcode

The Gcode operation does not generate a toolpath but instead adds a line or lines of G-code to the output

of the file. The Gcode operation is different from Gcode Macros,

as it is not tied to any event

but is output in the order it is included in the operations array.

Laser Operations

Laser operations become available when "Enable Laser" is selected in the Machine tab.

These operations are specific to certain machines, like the Makera Carvera, and can be safely ignored for other machines.

Indexed Operations

Indexed operations become available when "Indexed" is selected in the Process Ops tab.

These operations are specific to indexed stock and allow a user to create operations on different faces of a part.